About our Proprietary Technologies and Manufacturing Methods

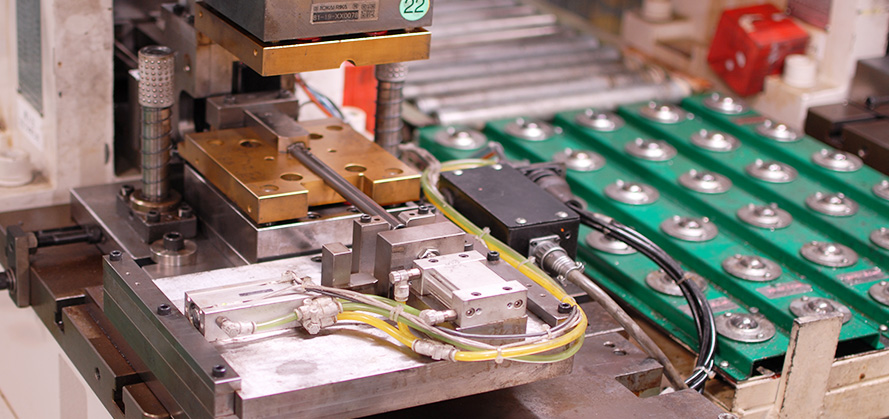

Presses

Our company specializes in pipe-forming presses, and we use them not only for domestic production but for overseas exports as well. We believe that our ability to press pipe shapes with precision and without deformation is a significant advantage for our company.

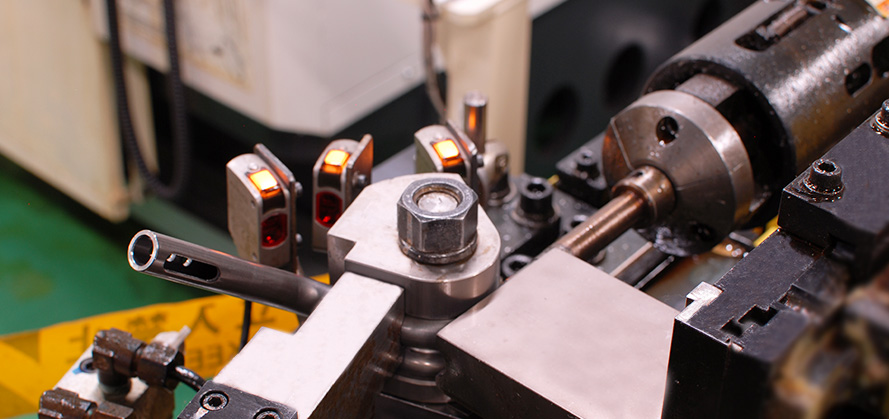

Benders

We specialize in the bending of hollow pipes and solid materials. A key issue is how to suppress shape deformation of the bent area. Solving that problem is one of the features of our products. Depending on the product, we can perform integrated press, cutting, and bender operations as well as automated production with the use of robots.

Cutting

We produce and ship numerous products that are cut through machining processes. We optimize our production processes by managing blade life, managing cutting oil, and minimizing machine time through the proprietary technologies we’ve developed.

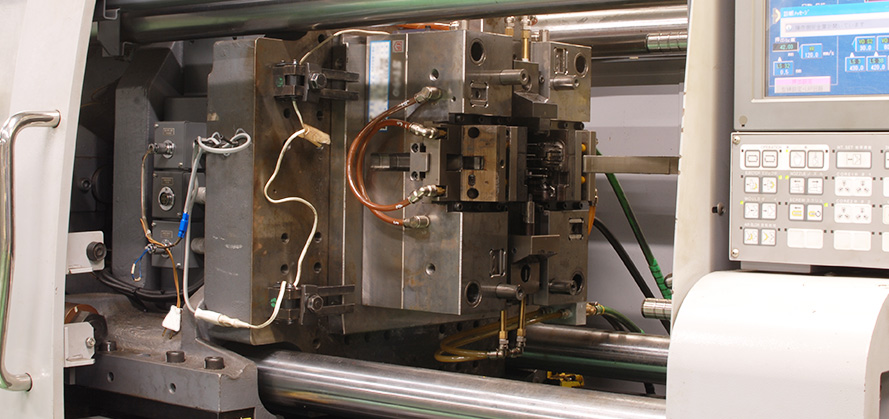

Plastic Molding

We handle production of everything from small objects to 450t-class objects. We can handle our customers’ special plastic material control audits, and we utilize transparent plastics, polyvinyl chloride, and glass-filled materials as well as insert molding and molding materials and methods that can accommodate appearance-related requirements. Additionally, we regularly perform in-house maintenance on sonic cleaners, wire cutters, milling machines, lathes, and other equipment in order to maintain quality assurance.

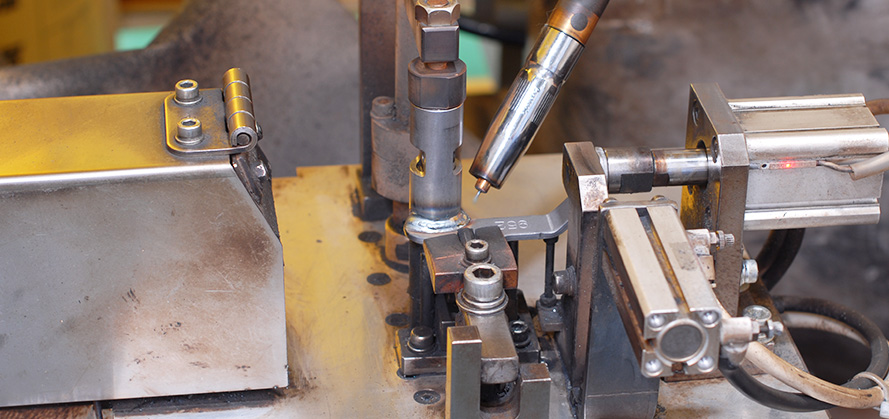

Welding and Similar Techniques

We have been using this production method ever since our founding. CO₂ welding, butt welding, projection welding, SP welding, ball threading, and orbital riveting are available for production. We make full use of the technologies we’ve developed over many years, such as current and voltage control, optimal torch angle configuration, arc optimization, spatter minimization, and weld penetration checks, to create products.

Assembly

We assemble shift levers, seatbelt components, and switch products. Most of our products are delivered directly to automobile manufacturers and are immediately incorporated into vehicles, which demands a higher level of quality assurance. In order to deliver products to customers, we use a variety of assembly methods, including gluing processes that use robots, as well as riveting, ultrasonic welding, heat welding, mechanical press-fitting, and imaging-based inspection. Switch products, by their very nature, require a specialized production environment with measures to eliminate dust and static electricity, and they are manufactured on a dedicated production floor by employees wearing special work clothing.

Hot Stamping and Pad Printing

We can handle printing on products.

Soldering

We perform soldering by hand. We also offer lead-free solder and ultrasonic cleaning.

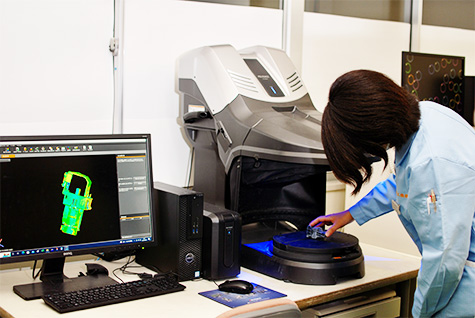

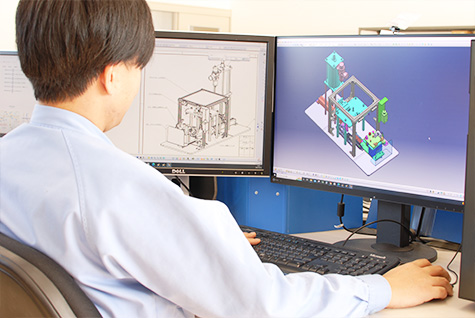

Other

We do CAD-based design of jigs, machinery, and equipment. We also do product research and can share technology through our production technology sample corner. In terms of measuring instruments, we have coordinate-measuring machines, imaging-based measuring instruments, projectors, Amsler instruments, and more.