Manufacturing Division No. 1

This division assembles and produces shift levers, seat belts, and switch products. The assembly line for shift levers, a safety-critical product, is equipped with automated inspection equipment to ensure quality control and quality assurance.

Manufacturing Division No. 2

This division produces a large number of components using various types of dies, machinery, and equipment for processes that include press work, cutting, plastic molding, and bending. With the use of robots and automated equipment, production is able to continue day and night.

The Die Maintenance Department is part of Manufacturing Division No. 2.

Sales Division

This division conducts sales activities aimed at regular customers. It works together with the Engineering Division to take orders, make proposals, hold meetings, and create prototypes. It also coordinates prototypes, scheduling management for mass production products, delivery, administration, internal production, production at the Thai plant, and various suppliers.

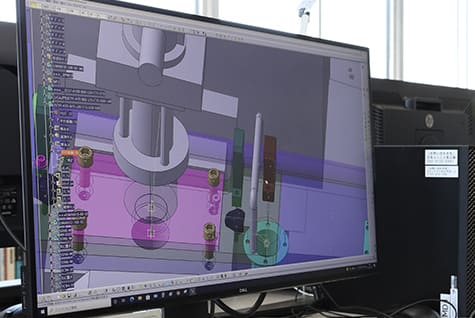

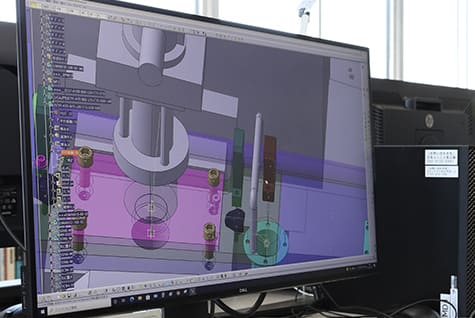

Engineering Division

The Engineering Division is responsible for process design, jig design, equipment design, die creation, setup of robots and other automated production equipment, development of proprietary products and equipment, and line upgrades for the company’s product manufacturing processes.

This division is in constant contact with customers and suppliers, collaborating on the creation or processes that will produce the best products.

We also provide support for overseas production by sending production lines, dies, jigs, and other equipment to our Thai plant.In conjunction with this role, this division is also responsible for providing support and guidance for the Engineering Division and other departments at Shinsei Koki Thailand, our local Thai subsidiary.

Quality Control Division

This division conducts quality control, measurement, evaluation, and shipping inspections for mass production products and components as well as calibration management for in-house measuring instruments. It also performs a wide range of quality-related tasks, such as handling audits of special processes (safety-critical processes) for customers, discussing and evaluating new product specifications together with customers, ensuring and improving quality both within the company and at suppliers, and monitoring quality performance. Another important task of this division is to train the Quality Control Division and other departments at Shinsei-koki Thailand.

Production Control Division

This division tabulates and evaluates productivity at the Nagano Plant and conducts production meetings. It also manages logistics on- and off-premises, packages products for export, delivers products procured from customers, suppliers, and overseas sources (Shinsei Koki Thailand), conducts progress management for receiving, conducts inventory management, and provides production instructions. Another important task of this division is to manage the progress of new products and design changes. Additionally, this division is responsible for inventory control for components that are needed for the manufacturing of products, other components, intermediate products, and so on, and it provides instruction and training for service parts management and Shinsei-koki Thailand’s Production Control Division.